Last Updated JULY 2025

5 Ways Manufacturers Can Cut Costs with Effective Maintenance Practices

On the shop floor where every minute of downtime can translate into thousands of dollars lost, maintenance isn’t just a support function, it’s a strategic lever. If you're tasked with optimizing performance and controlling costs, effective maintenance practices offer a high-impact opportunity to drive measurable results. Whether you're evaluating new systems or refining existing protocols, these insights will help you make smarter, more cost-effective decisions.

1. Avoid Reactive Maintenance

Reactive maintenance—fixing equipment only after it breaks—can be extremely costly. According to Reliable Plant, unplanned maintenance takes 3 to 9 times longer than planned work, leading to wasted labor, delayed production and increased overtime costs.

Why it’s costly:

- Emergency repairs often require expedited shipping for parts and premium labor rates.

- Downtime disrupts production schedules and can delay customer deliveries.

- It increases wear on other equipment due to sudden load shifts or overuse.

2. Implement Preventive Maintenance

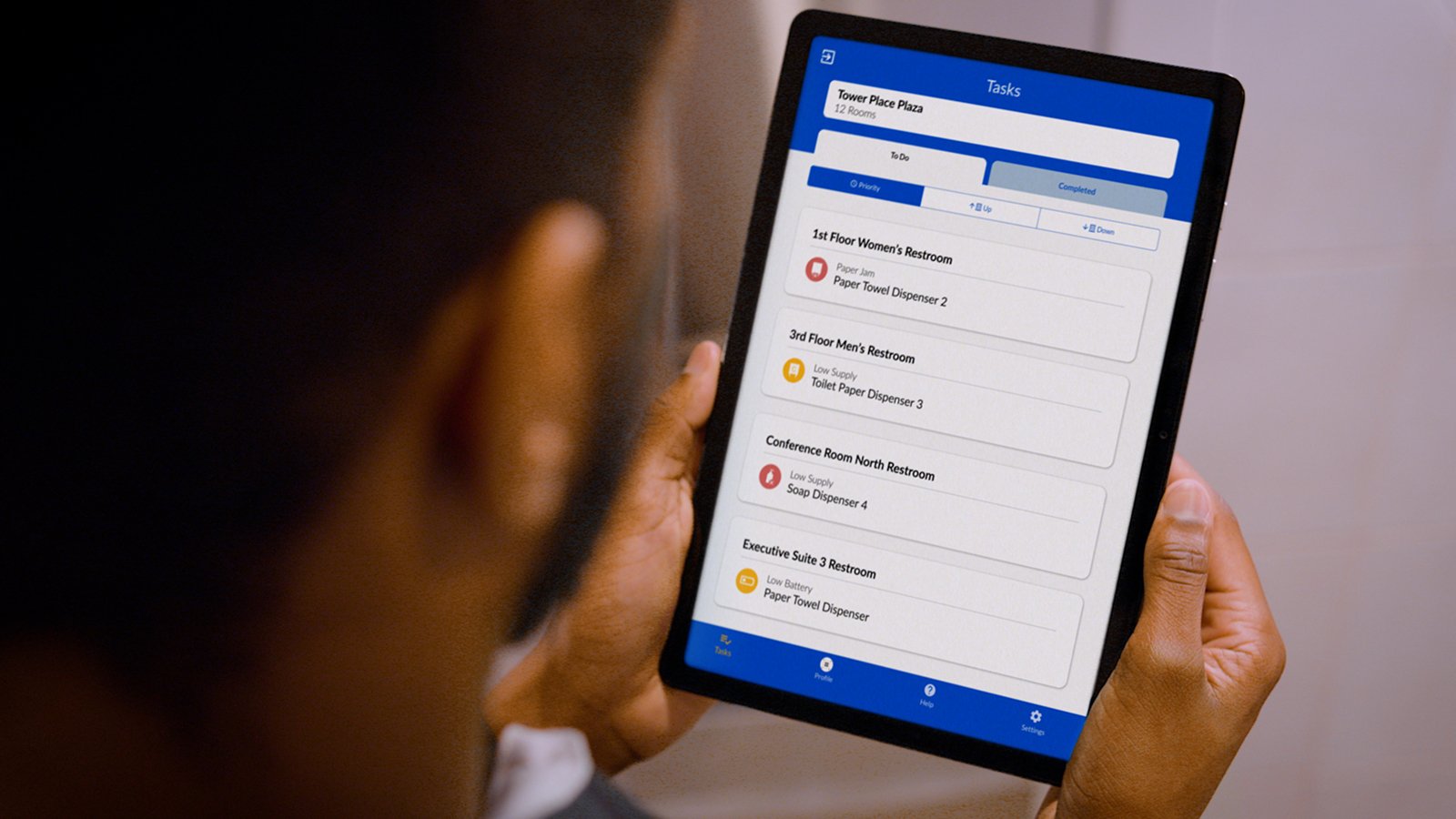

Preventive maintenance involves scheduling regular, planned maintenance activities based on time intervals or equipment usage. This proactive approach helps identify and resolve minor issues before they turn into major failures.

Benefits:

- Reduces the frequency and severity of equipment breakdowns.

- Extends the lifespan of machinery and tools.

- Improves safety by ensuring equipment is always in optimal condition.

- Enhances production reliability and reduces unplanned downtime.

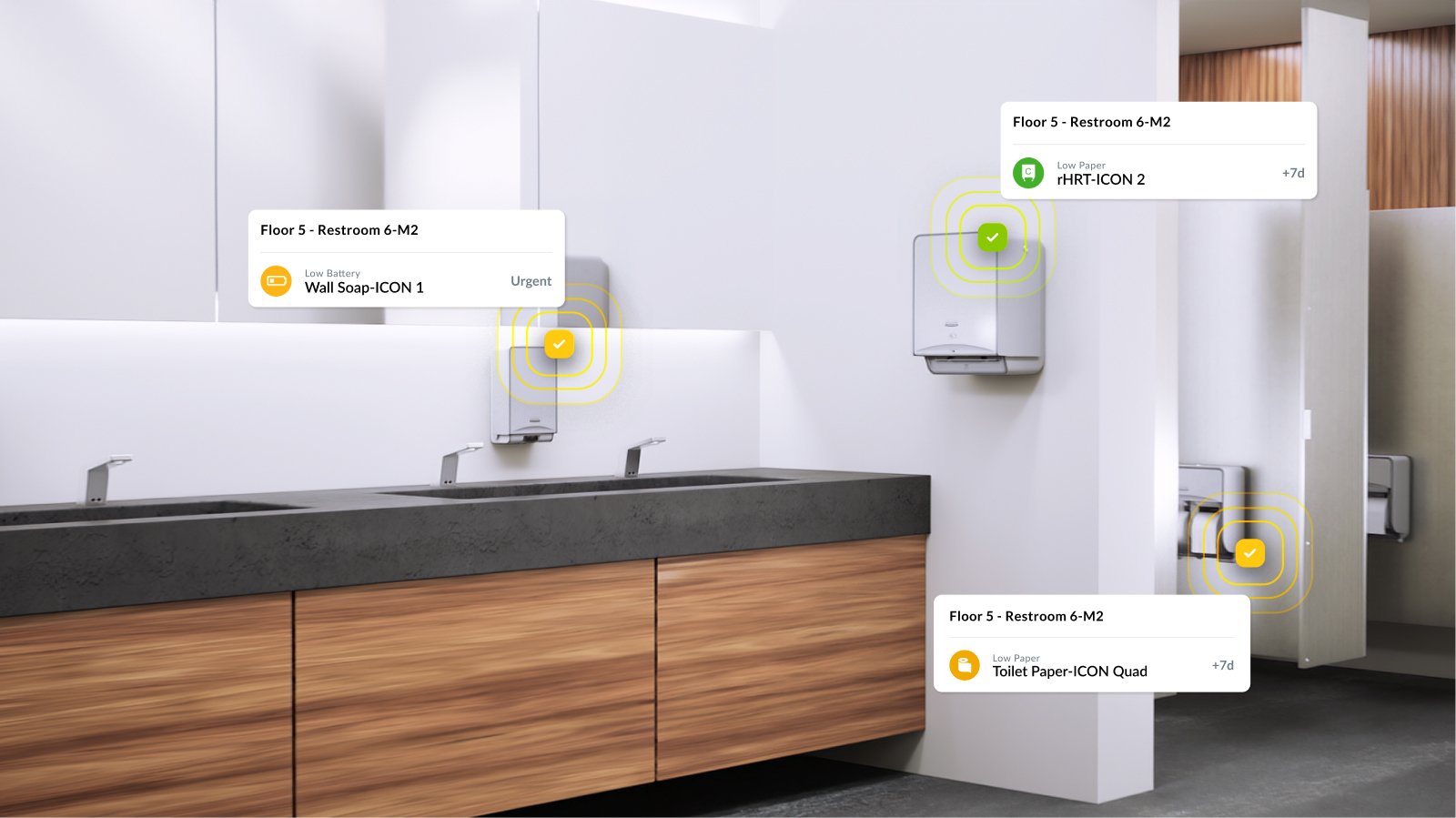

3. Use Predictive Maintenance

Predictive maintenance uses real-time data from sensors and analytics tools to forecast when equipment is likely to fail. This allows maintenance teams to intervene just before a breakdown occurs.

Technologies involved:

- Vibration analysis

- Thermal imaging

- Oil analysis

- IoT-enabled sensors and AI-driven analytics

Benefits:

- Reduces unnecessary maintenance tasks.

- Minimizes unexpected downtime.

- Optimizes spare parts inventory by predicting needs.

4. Train Maintenance Staff

Well-trained maintenance personnel are essential for efficient operations. Investing in training ensures your team can diagnose issues accurately, perform repairs correctly and use tools and technology effectively.

Training areas to focus on:

- Equipment-specific maintenance procedures

- Safety protocols and compliance

- Use of diagnostic tools and software

Benefits:

- Reduces human error and rework.

- Increases team confidence and morale.

- Enhances the speed and quality of repairs.

5. Conduct Regular Inspections

Routine inspections are a low-cost, high-impact way to catch problems early. These inspections can be visual checks, performance tests or sensor-based diagnostics.

What to inspect:

- Wear and tear on moving parts

- Fluid levels and leaks

- Electrical connections and wiring

- Safety guards and emergency stops

Benefits:

- Prevents small issues from becoming major failures.

- Improves compliance with safety and quality standards.

- Improves compliance with safety and quality standards.

Bonus Strategies for Cost-Effective Maintenance

Standardize Maintenance Procedures

Create clear, step-by-step procedures for all maintenance tasks. Standardization ensures consistency, reduces training time and minimizes errors.

Implement Total Productive Maintenance (TPM)

TPM involves all employees—from operators to managers—in maintaining equipment. This shared responsibility improves equipment reliability and fosters a culture of continuous improvement.

Schedule Maintenance During Downtime

Plan maintenance during off-hours, shift changes or scheduled production breaks to avoid disrupting operations.

Optimize Cleaning Procedures

Efficient cleaning not only improves hygiene but also prevents buildup that can cause equipment wear or contamination. Use the right tools and materials to clean without damaging sensitive components.